Calibration environmental conditions

The calibration environmental conditions and their requirements are as follows:

a) Ambient temperature: 20 °C ± 5 °C

b) Relative humidity: 30-60%

c) There are no measurable electric, magnetic, positive and negative ions around

d) Ground wire, ground wire resistance <100Ω

2, Calibration equipment

The equipment used for calibration shall be calibrated by the metrology technical organization to meet the calibration requirements and within the validity period.

Calibration equipment mainly includes: DC high voltage meter, DC high voltage power supply, standard flat electrode, distance adjuster and so on. The test chart is located on the center line of the calibration plate. The block diagram of the non-contact electrostatic voltmeter calibration device is as follows:

The equipment and equipment requirements are as follows:

C——calibrated product: static test table

D1——DC high voltage power supply: output range -30KV~+30KV, continuously adjustable, or minimum step 1V, the measurement uncertainty is less than 1/4 of the allowable error limit of the calibration table;

D2——DC high voltage meter: measuring range -40KV~+40KV, the measurement uncertainty is less than 1/4 of the allowable error limit of the calibration table;

D3——Standard plate electrode: The plate electrode should be round or square rounded. The radius of curvature of the edge of the electrode should not cause corona. It is recommended to wrap the edge of the electrode with insulating material; the area of the plate should be large enough. The diameter or side length should be no less than 0.4m. Our calibration plate size is 600mm*600mm square stainless steel plate.

——Protection resistance: The resistance of the resistor should be >20KV, the protection current and the current of the human body are <5mA, and the resistance value meets the requirements of the following formula:

Where: for protection of resistance, the unit is ohm (Ω);

The resistance of the insulating bracket is in ohms (Ω), the resistance is >1013Ω, and the compressive strength is >25KV.

The above two resistors, their different resistance values, may cause the detected static voltage values to be different under the same standard voltage.

S1 - insulated bracket

S2——scale, measuring range: 5mm~700mm, measurement uncertainty less than 0.5mm

S3——Distance adjuster: Place the test meter on the calibration device. The front end of the test chart should be extended. The geometry and material of the support should be minimized to affect the electric field distribution around the front end of the test chart.

Ion bar> AP&T AP-DB1233 Cleanroom Ceiling Ionizer > AP-DB1229 Laminar Flow Ion Bar > AP-AB1228 High Speed Intelligent Self-balancing Ion Bar > AP-AB1103 Cheapest Electroshock-proof AC Ionizer Bar > AP-AB1602A Explosion-proof AC Ionizing Bar > AP-DB1227 Long-distance Electrostatic lonizing Bar > AP-GB1106 Static Generator > AP-AB1218 Air Source Anti-Electric Shock Pulse AC Ion Bar > AP-AB1216 Air Source Electric Shock Proof Pulse AC Ion Bar > AP-AB1108 Electric Shock Proof High Efficiency AC Ion Bar

Ion bar> AP&T AP-DB1233 Cleanroom Ceiling Ionizer > AP-DB1229 Laminar Flow Ion Bar > AP-AB1228 High Speed Intelligent Self-balancing Ion Bar > AP-AB1103 Cheapest Electroshock-proof AC Ionizer Bar > AP-AB1602A Explosion-proof AC Ionizing Bar > AP-DB1227 Long-distance Electrostatic lonizing Bar > AP-GB1106 Static Generator > AP-AB1218 Air Source Anti-Electric Shock Pulse AC Ion Bar > AP-AB1216 Air Source Electric Shock Proof Pulse AC Ion Bar > AP-AB1108 Electric Shock Proof High Efficiency AC Ion Bar Ionizing air blower> AP-DJ2811 Intelligent Control LCD Display Ionizing Air Blower > AP-DJ1811 Intelligent Control High Efficiency Static Eliminator > AP-DC2451-001 Self-Cleaning Desktop Ionizer Fan > AP-AC2459 Cross Flow Ionizing Air Blower > AP-DC2453 Desktop Mini Ionizing Air Blower > AP-DJ2814 ap&t industrial overhead anti static esd air ionizer > AP-DJ2711 Intelligent Remote Control DC Anti Static Air Blower > AP-DJ2712 Intelligent Control Network Ion Fan > AP-DJ2716 Intelligent Control Network Overhead Ionizing Air Blower > AP-DC2452-100C Suspended Ionizing Air Blower

Ionizing air blower> AP-DJ2811 Intelligent Control LCD Display Ionizing Air Blower > AP-DJ1811 Intelligent Control High Efficiency Static Eliminator > AP-DC2451-001 Self-Cleaning Desktop Ionizer Fan > AP-AC2459 Cross Flow Ionizing Air Blower > AP-DC2453 Desktop Mini Ionizing Air Blower > AP-DJ2814 ap&t industrial overhead anti static esd air ionizer > AP-DJ2711 Intelligent Remote Control DC Anti Static Air Blower > AP-DJ2712 Intelligent Control Network Ion Fan > AP-DJ2716 Intelligent Control Network Overhead Ionizing Air Blower > AP-DC2452-100C Suspended Ionizing Air Blower Dust removal series> AP&T AP-AZ9502 High-Frequency AC Ionizing Air Nozzle > AP-AZ1211 esd anti static antistatic pistol > AP-AC2456 High Efficiency Ionizing Air Gun > AP-DC3203 High-performance Ionizing Air Nozzle > AP-AC2454-A Ionizing Air Nozzle > AP-AZ5203 Electroshock-proof Ion Pen > AP-AZ3201 Inductive Ionizing Air Snake > AP-AC0001 AP&T Anti Static Brush

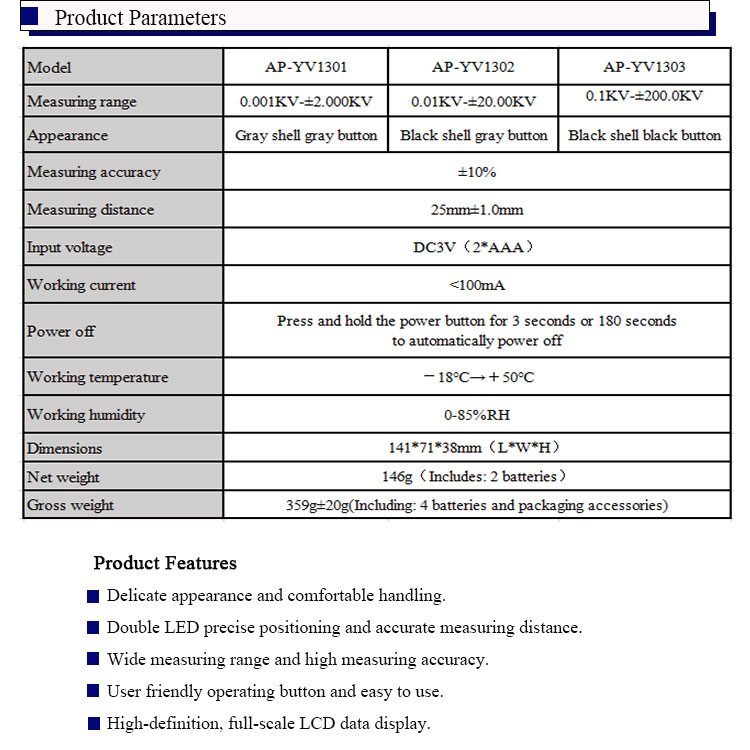

Dust removal series> AP&T AP-AZ9502 High-Frequency AC Ionizing Air Nozzle > AP-AZ1211 esd anti static antistatic pistol > AP-AC2456 High Efficiency Ionizing Air Gun > AP-DC3203 High-performance Ionizing Air Nozzle > AP-AC2454-A Ionizing Air Nozzle > AP-AZ5203 Electroshock-proof Ion Pen > AP-AZ3201 Inductive Ionizing Air Snake > AP-AC0001 AP&T Anti Static Brush Static Meter> AP-YV3302 Intelligent esd Electrostatic Static Sensor > AP-YF1201 Explosion-proof Static Meter > AP-YV3303 Constant Portable Scs Esd Static Electricity Monitor > AP-YV1301 Static Meter-Measuring Range(0.001-±2.000) > AP-YV1302 Static Meter-Measuring Range(0.01-±20.00) > AP-YV1303 Static Meter-Measuring Range(0.1-±200.0)

Static Meter> AP-YV3302 Intelligent esd Electrostatic Static Sensor > AP-YF1201 Explosion-proof Static Meter > AP-YV3303 Constant Portable Scs Esd Static Electricity Monitor > AP-YV1301 Static Meter-Measuring Range(0.001-±2.000) > AP-YV1302 Static Meter-Measuring Range(0.01-±20.00) > AP-YV1303 Static Meter-Measuring Range(0.1-±200.0) Static sensor

Static sensor Power supply> AP-AY2201 AC High Voltage Power Supply > AP-AY450X-850X high voltage anti static electrostatic discharge eliminator power supply > AP-DY6702 IMS Power Supply > AP-AY2506 AC High-voltage Power Supply > AP-AY1506 AC High-voltage Power Supply > AP-AY2505 AC High-voltage Power Supply > AP-AY1505 AC High-voltage Power Supply > AP-AY2504 AC High-voltage Power Supply > AP-AY1504 AC High-voltage Power Supply > AP-AY2503 AC High-voltage Power Supply

Power supply> AP-AY2201 AC High Voltage Power Supply > AP-AY450X-850X high voltage anti static electrostatic discharge eliminator power supply > AP-DY6702 IMS Power Supply > AP-AY2506 AC High-voltage Power Supply > AP-AY1506 AC High-voltage Power Supply > AP-AY2505 AC High-voltage Power Supply > AP-AY1505 AC High-voltage Power Supply > AP-AY2504 AC High-voltage Power Supply > AP-AY1504 AC High-voltage Power Supply > AP-AY2503 AC High-voltage Power Supply 中文

中文

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)