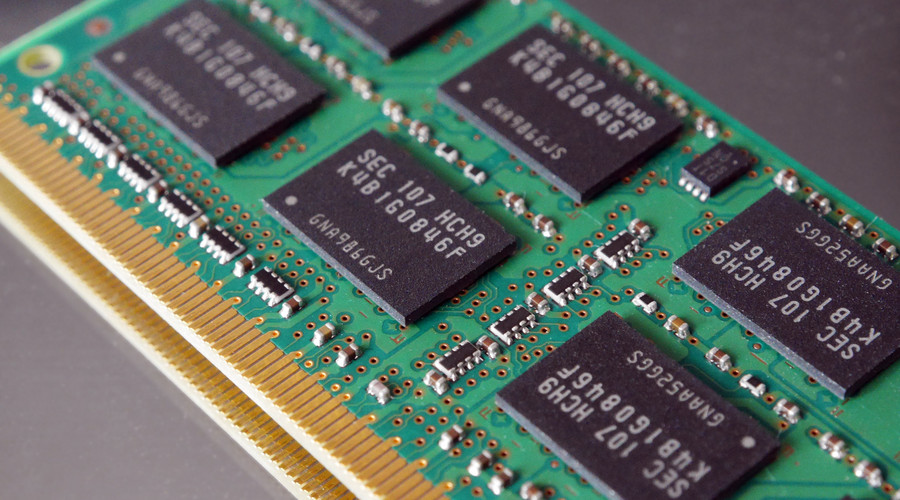

In the semiconductor device manufacturing workshop, the yield of the ultra-large scale integrated circuit is greatly reduced due to the adsorption of dust on the chip. The production workshop operators wear clean overalls. If the human body is charged with static electricity, it is easy to absorb dust, dirt, etc. If these dusts and dirt are brought to the operation site, it will affect the product quality, deteriorate the product performance, and greatly reduce the yield. . If the radius of the adsorbed dust particles is greater than the line width, and the film thickness is below, the product is most likely to be scrapped.

Therefore, it is necessary to establish an ESD protection system during processing and packaging. The IC packaging production line has stricter requirements on static electricity. In order to ensure the normal operation of the production line, the overall decoration of the anti-static building materials for its clean factory, and the hardware measures for all the personnel entering and leaving the clean factory to be equipped with anti-static clothing, the packaging enterprises can be based on the relevant national standards and the actual situation of the enterprise. Develop enterprise standards or specific requirements for anti-static to match the normal operation of the packaging line.

Because there are many types of equipment for dust removal and static elimination, how to choose the product that suits you is mainly determined according to the conditions on the production line. Here are some of the equipment that remove dust and static electricity:

1. Ion air gun: It is characterized by hand-held type, and the operation mode is very random. It is more suitable for use in the inspection part. The inspector can see that there is dust there, just pick up the air gun and blow it.

2. ion tuyere: it is a fixed product, small size, does not occupy the place, it is more suitable for the station or a small space in a small station. It can also be made into pedal and inductive.

3. ion wind snake: It has three styles: ordinary, inductive and pedal-type, to meet the needs of customers in different environments on the production site. It is suitable for use in a space where there is no need for personnel to operate, but it is necessary to adjust the direction of the dust blowing.

In addition to the above products, an ion fan is required in part of the assembly line and the operation station, thereby reducing the accumulation of static electricity and preventing the product from being unknowingly broken down. We can choose our hanging or desktop ion fan, which has large power-dissipation area and does not occupy working space. It can be selected according to the size of the workbench or the width of the pipeline.

Shanghai Anping Electrostatic Technology Co., Ltd. is a professional supplier of industrial anti-static overall solutions, focusing on research and development of various types of static eliminators such as ion fans, ion wind guns, ion bars, ion wind snakes, and various electrostatic testing equipment and clean rooms. A professional manufacturer of consumables, and strive to create a static-free workshop for you!