In gravure, accidental fires can cause serious harm to production. This kind of fire problem is caused by the static electricity on the surface of the coil to discharge the surrounding grounded parts (such as electric sparks), which caused the flammable solvent in the fuel tank. This usually happens when the material enters and leaves the corners of the printing envelope (see the area marked on the way). Especially when the printing ink is more or less conductive inks such as gold, silver, or black, it is more likely to catch fire. Electrical conductivity makes it easier to generate sparks.

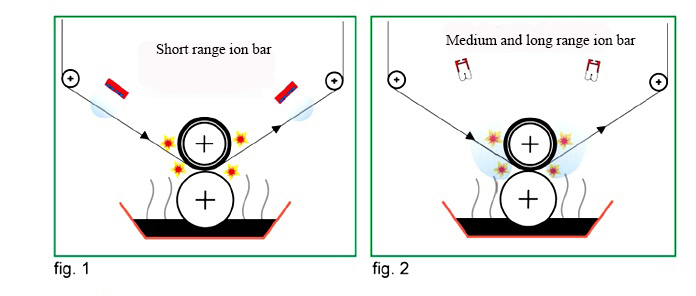

The typical installation of a short-acting ion rod is shown in Figure 1. Although it is better than nothing, because of its short acting distance and the proximity of the rod to the material, there are several disadvantages:

1. Cannot cover the entire area that needs to be solved for static electricity.

2. The stick will soon be contaminated.

3. A smaller coverage area results in a shorter residence time of the coil in the ionic area, which results in a poorer electrostatic neutralization effect.

4. The static elimination rod may be easily damaged due to the break of the coil.

The gas source ion rod can be installed in the area away from the coil (see Figure 2), and the effective distance can reach 150mm. This will completely eliminate static electricity in the static control area (as shown in the figure), and also reduce the probability of contamination and damage of the ion rod, thereby solving the above problems.