1. PET material has adsorption phenomenon, which causes the machine to run alarm. Cannot continue printing normally, need to shut down for finishing.

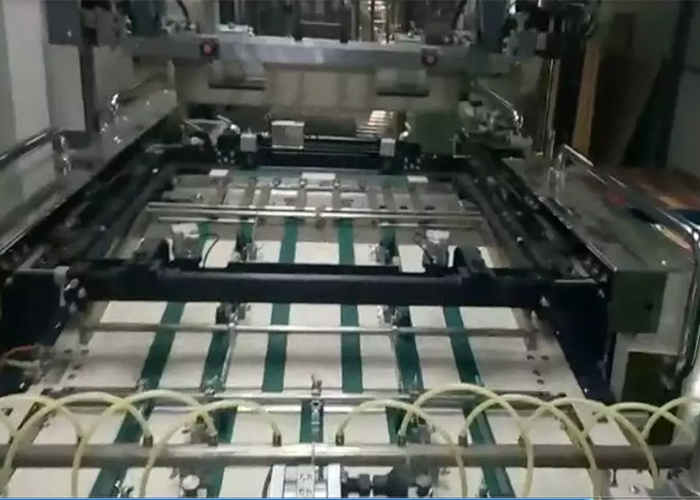

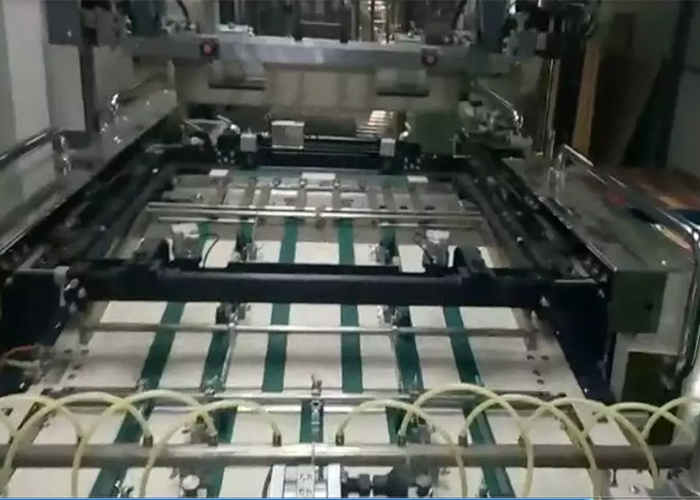

2. When PET material passes through the conveyor belt during operation, it cannot be conveyed smoothly.

3. When PET is printing, due to excessive static electricity, the material has dust attracted to the surface of the product, which affects the quality of the product.

4. After the PET is printed, the finishing area prevents the products from being sorted out. The more the products are, the more uneven the layers appear and the harder to arrange.

The above-mentioned on-site inspections are typical phenomena caused by excessive static electricity. How to eliminate static electricity in screen printing?

Currently, there are two basic and basic methods for controlling static electricity:

1. The equipment is well grounded "but it cannot effectively eliminate static electricity on the material". The grounding of the machine is the most basic requirement at present. ① Good grounding allows the machine to operate efficiently without other problems caused by static electricity. However, when producing materials with static electricity, the static electricity on the materials can be conducted away when the grounding is done, but the effect is not significant. If the value of static electricity is as high as tens of thousands of volts, it is basically ineffective. If the ground can completely eliminate static electricity, there will be no static eliminator.

2. Use a static eliminator "can effectively neutralize the static electricity on the surface of the material". Use static eliminator: High-voltage static eliminator ionizes air molecules to free electrons from oxygen molecules, thereby generating negatively charged electrons and positively charged oxygen ions. If the material is positively charged, it can be neutralized by negatively charged electrons; conversely, if the material is negatively charged, it can be neutralized by positively charged oxygen ions. This method can maximize the elimination of static electricity in the production process and is currently the most desirable method for screen printing.

Anping has visited the production screen printer manufacturers and direct users on the spot throughout the country based on the actual conditions over the years, and according to the operating speed of the equipment, the attributes of the production materials. Develop a variety of static elimination rods and electrostatic ion fans to effectively eliminate static electricity on products. Through detailed communication with customers in various aspects, the customer has solved the static electricity problem through the following two points.

1. Install a static ionization fan in the process of the product passing through the conveyor belt, first effectively eliminate the static electricity generated by the friction of the product when passing through the insulating conveyor belt, and reduce the static value on the product.

2. Install a static ionization fan in the printing and finishing of the product. After the product is printed, it will generate a large amount of static electricity due to the frictional inertia of the feeder during the paper feeding process. This is also the main reason for the uneven finishing of the product. The installation of a static ionization fan above the can effectively eliminate the static electricity on the surface of the product and the fine dust absorbed by the product due to static electricity. Reduce the defective rate and improve production efficiency.