Electrostatic solution for UV flatbed and coil machine equipment

Now more and more manufacturers of UV flatbed and coil machine equipment pay more attention to the control of static electricity. After all, the equipment is relatively expensive, and there are many small details to pay attention to during the production process.

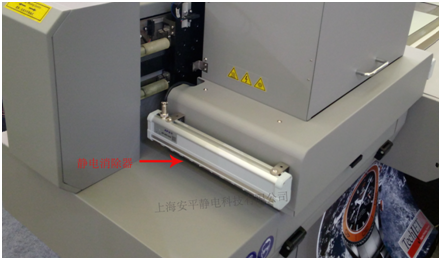

1. Select 24V static eliminator products

The model of static eliminator is AP-AB1205

2.Installation location plan

The static eliminator is usually installed on the two outer sides of the front of the chassis, with convenient wiring, short size and good elimination effect.

3, requirements for fixed static eliminators

Installed on the outside of the front chassis. The power cable of the 24V static eliminator can be connected to the 24V port in the front panel card. After power up, the product works. The needle seat surface of the static eliminator must be installed at a height of 3-5CM from the printing medium, and the side must be 2cm away from the metal surface of the casing to ensure the best static elimination effect when the static eliminator works.

4, 24V static eliminator power requirements

The ground wire in the working power line of the 24V static eliminator needs to have a good ground.

5. 24V static eliminator working requirements

1) It is recommended that the static eliminator be controlled by independent power supply. It can be made as a button to turn on and off the static eliminator.

2) Turn on the static eliminator when printing materials with static electricity, and turn off the static eliminator when printing non-static materials "including metal, wood materials".

6. Maintenance requirements for static eliminators

The static eliminator is affected by the environmental factors of the printing area. If the static eliminator is in working state for a long time, it will cause different degrees of adsorption of impurities on the needle tip, resulting in poor static elimination effect. Regular cleaning and maintenance are required.