Do you have problems of one kind or another?

What if the slit end face is not neat?

When the trademark is cut, the material is entangled around the machine, causing the paper to be unfavorable and affecting the cutting standard.

How do you deal with the dust and fluff in the air above the paper?

These may be caused by the generation of static electricity.

Static electricity is a problem often presented during the cutting process. The trademark cutting machine cuts off small objects and divides them into sections. At the moment of cutting, the static electricity is too large.

How to solve the problem of static electricity generation?

Installing a static eliminator at the cut position of the mark eliminates a large amount of static electricity generated during cutting. The most common method of eliminating static electricity during the slitting process is to use an ion wind bar.

The ion wind bar generates a large amount of positive and negative charges by air ionization, and blows positive and negative charges by a fan to form a positive and negative electric charge, which neutralizes the charge on the surface of the object. When the surface of the object is negatively charged, the ion wind bar will attract a positive charge in the airflow. When the surface of the object is positively charged, the ion wind bar will attract the negative charge in the current, so that the static electricity on the surface of the object is Neutralize to achieve the purpose of eliminating static electricity.

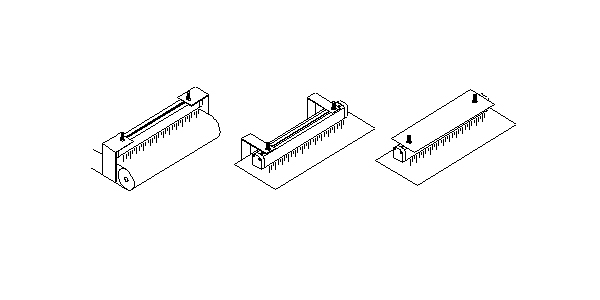

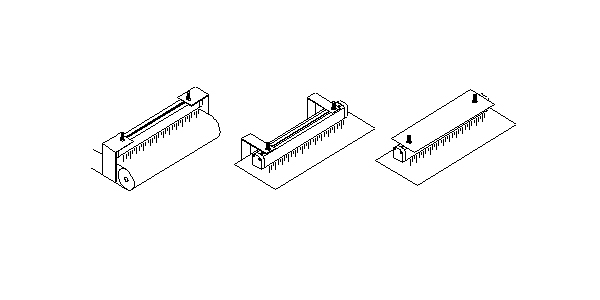

Installation diagram:

Choose the best power-off position and install the rod and the matching high-voltage power supply firmly.

Insert the high voltage plug of the rod into the high voltage output connector of the high voltage power supply.

Connect the ground terminal of the rod to the high voltage power ground stud

Turn on the power switch, the switch indicator light shows the power supply, the electrode needle will produce positive and negative air ions to neutralize the static electricity on the surface of the object.